Southampton Biopharma Tube Manufacturer Completes Infrastructure on Warrington Site Rehab

NewAge Industries, Southampton, having completed the basic build-out of its new manufacturing facility in Warrington, is moving onto the next phase: Installation and testing of interior cleanrooms. Medical Plastics News covered the story.

When completed, the facility will make and ship tubing that, owing to volumes driven by COVID-19, has proven important to the biopharma industry.

“We purchased the building over a year ago,” said Ken Baker, CEO. “There was a lot of planning, engineering, and permitting that had to take place. It took time to order and receive the extrusion equipment, all of which is U.S. made. And we’re glad to be moving past the prep work. The construction team has built out some of the cleanrooms and is working hard to complete others.”

The 90,000-sq. ft building, on seven acres, will house several individual cleanrooms for extruding several types of high-purity hosing and thermoplastic elastomer (TPE) tubing.

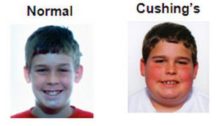

TPE tubing is rubber-like in its flexibility but is treated to be resistant to high temperatures and harsh chemicals. It is a medical-industry staple that has taken on even more importance during the COVID-19 outbreak.

More on this story is at Medical Plastics News.

Connect With Your Community

Subscribe for stories that matter!

"*" indicates required fields